.jpg)

The chief advantage of these systems lies in unified access to real-time production data. This enables deep insight into the actual cost of each product and helps to spot bottlenecks and identify areas for cost reductions and workflow optimizations. Work in process (WIP), sometimes called work in progress, is a type of inventory that lies in the manufacturing pipeline between the raw materials and finished goods inventories. In other words, WIP is the part of a company’s overall inventory that has begun being processed but is not yet finished.

Intuit does not have any responsibility for updating or revising any information presented herein. Accordingly, the information provided should not be relied upon as a substitute for independent research. Intuit does not warrant that the material contained herein will continue to be accurate nor that it is completely free of errors when published. High-quality WIP items progress more smoothly through the production process, reducing the risk of delays. Determine optimal reorder points for WIP to avoid stockouts and production delays.

- If your procurement process looks anything like the following three scenarios, you should track and calculate your WIP inventory.

- WIP inventory represents a transitional phase between raw materials and finished goods.

- WIP inventory is a key component of your company’s assets and must be accurately reported in financial statements.

- As unsung heroes of financial management, outsourced controllers can bring significant benefits that go well beyond basic bookkeeping.

- Since WIP inventory is an inventory asset, neglecting to include it on your business’ balance sheet can cause your total inventory to be undervalued.

- In conclusion, regularly calculating WIP inventory leads to better financial transparency, smoother operations, and enhanced profitability.

- With a diverse global team, Qoblex serves a customer base in over 40 countries, making it a reliable partner for businesses worldwide.

Steps in Process Costing

In accounting, WIP is an asset and designates the value of unfinished goods at the end of a financial period. Similarly to inventory and raw materials, the WIP inventory is accounted for as an asset in the balance sheet. All costs related to the WIP inventory, including the costs of raw materials, overhead costs, and labor costs, need to be considered for the balance sheet to be accurate.

- Accurately knowing what your WIP inventory is can impact the company’s balance sheet.

- The work in process inventory formula consists of the ending work inventory for that period, and the beginning work inventory for the next one.

- Be sure to partner with software service providers such as Emergeapp to help you achieve your inventory management goals.

- It is also important to keep tabs on these numbers when calculating the inventory to sales ratio, which is just one of many inventory KPIs.

- In the world of fulfillment and inventory management, understanding Work in Process (WIP) inventory is crucial for businesses of all sizes.

- WIP is also crucial for financial management, allowing businesses to allocate costs accurately and assess profitability.

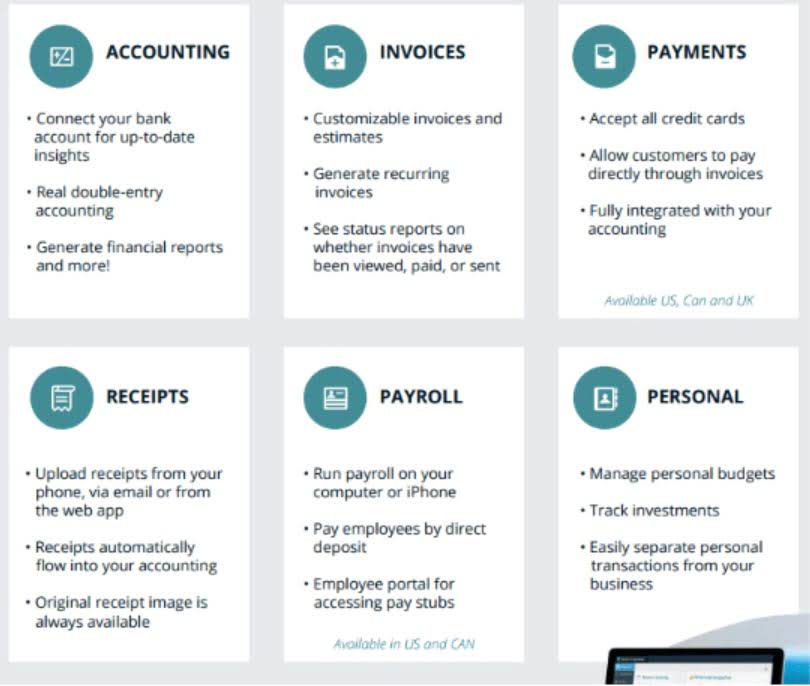

- Sign-up for QuickBooks today or start your 30-day free trial and take control of your inventory management.

WIP can help manufacturers identify the need to optimize production processes, reduce cycle time or improve inventory management. A high WIP may indicate inefficiencies in terms of both production processes and finances. That’s because WIP comes with storage costs, diverting money that could otherwise be invested elsewhere. Implementing advanced inventory management tools further enhances efficiency, reduces waste, and ensures smoother production cycles. Strategies such as lean manufacturing, improved supplier collaboration, and accurate demand forecasting enable businesses to stay ahead of the competition. By using this formula, businesses can maintain an accurate, up-to-date view of their WIP inventory.

What is the importance of WIP Inventory in fulfillment?

To calculate beginning WIP inventory, determine the ending WIP’s inventory from the prior period and bring it over as the beginning figure of the new financial period. The beginning work-in-process inventory represents the value of all unfinished goods at the beginning of the new accounting period. In other words, it is the WIP asset section of the balance sheet of the previous accounting period. The beginning WIP inventory cost refers to the previous accounting period’s asset section of the balance sheet. To calculate the beginning WIP inventory, determine the ending WIPs inventory from the previous period and carry it over as the beginning figure for the new financial period.

Get manufacturing know-how delivered to your inbox!

And one thing that these professions agree on is that it’s usually best to minimize work in process inventory. ABC Publishing starts the quarter with a work-in-process inventory of $25,000. This includes the glues, leather for bindings, and specialized paper for a particular book series. Work in process inventory, or WIP inventory, shouldn’t be confused with beginning work in process inventory formula work in progress meetings or updates, as used in general business and project management. This content is for information purposes only and should not be considered legal, accounting or tax advice, or a substitute for obtaining professional advice specific to your business. No assurance is given that the information is comprehensive in its coverage or that it is suitable in dealing with a customer’s particular situation.

.jpg)

In most cases, depreciation expenses should not be considered in the cost of items purchased. Nor should you include the cost of supplies, equipment, or services that are used for purposes other than building inventory. Failing to monitor your manufacturing company’s WIP can have negative financial and operational outcomes.

.jpg)

Determining Cost of Goods Sold (COGS) & Using the Data for Financial Strategies

As an added perk, minimizing WIP may cut your storage costs and trim the odds of obsolescence. On the income statement, WIP inventory affects the cost of goods sold (COGS). As WIP transitions to finished goods, these costs are recognized in COGS, influencing gross profit margins.

What Is Work in Process Inventory and How to Calculate It

You might have always been thinking about how to find work in process inventory. Now that you’ve got a grip on what WIP inventory is, you might be wondering why it’s important to classify in the first place. As indicated earlier, the beginning WIP of a company is derived from the ending WIP inventory of the immediate previous WIP inventory. Work in process is a slightly different term for quickly manufactured goods. If you need assistance with warehousing and fulfillment, partner with a 3PL that has the expertise, industry knowledge, and technology to help you make better business decisions.

Furthermore, the different work-in-progress formulas can help discover production bottlenecks and improve the overall workflow. In order to do so, businesses can analyze all the different stages of the manufacturing process. Either way, determining the value of work in progress can be time consuming, so companies try to minimize the WIP directly before the end of the accounting period. Work in process is the term for a product that is being manufactured, but which is not yet completed. That is, WIP doesn’t include raw materials that have not been used yet or completed goods. Work in process inventory is an asset The ending work in process inventory is simply the cost of partially completed work as of the end of the accounting period.

Continuous Monitoring and Tracking:

The key distinction is that Work in Process relates to goods moving through quick production, while Work in Progress involves projects that require multiple stages over a longer period. By understanding these distinctions, businesses can improve their production and project management, optimizing workflows and resource allocation. WIP is also crucial for financial management, allowing businesses to allocate costs accurately and assess profitability.

.jpg)

.jpg)